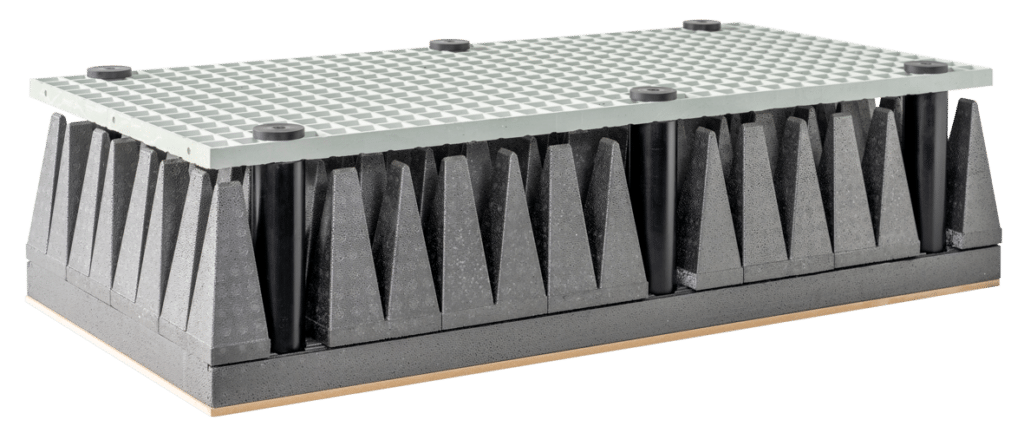

DMAS pyramidal RF absorbers offer great performance as well as exceptional material properties due to the use of polystyrene (EPS). This carbon loaded closed-cell absorbing material ensures stable performance without leakage of carbon particles keeping your facility clean and tidy.

In general, our RF absorbers are divided into two product categories: hybrid and microwave absorbers. Perfectly tuned for use in combination with a ferrite tile base, DMAS hybrid EMC pyramidal absorbers are primarily designed for EMC testing applications in anechoic chambers. This proven cascade design method has been incorporated by our distributors since 2011 and is successfully being utilized in numerous semi anechoic chambers around the world.

Alternatively, we offer microwave absorbers for antenna measurement applications. Thanks to recent updates to our ’Javelin’” pyramidal absorber range, we have greatly improved the pyramidal RF absorbing features by enhancing its pyramid shape without compromising durability and rigidity. Interested in comparison between traditional foam material and EPS? Read our blog post.

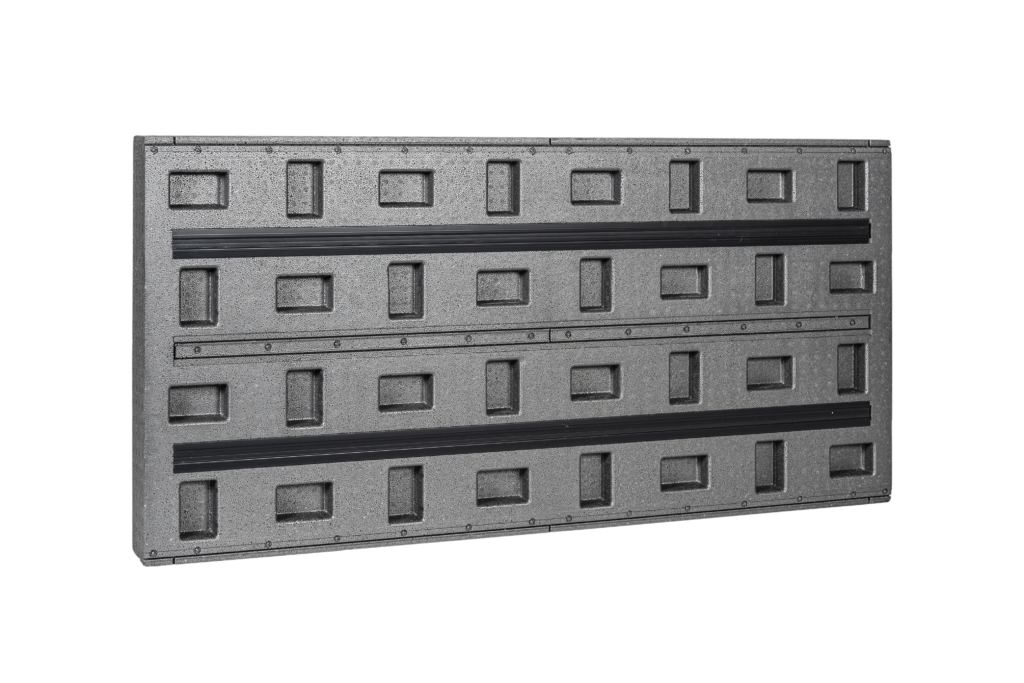

Most chamber solutions that use microwave pyramid absorbers have the floor completely covered making it impossible to reach the Equipment Under Test (EUT) without removing floor absorbers. A laborious and time-consuming process. Every time doing so risking damages to pyramid tips as well. Thankfully, you can opt to make use of DMAS walkway absorbers for easy access to AUT/EUT making the removal absorbers to create a pathway a thing of the past!

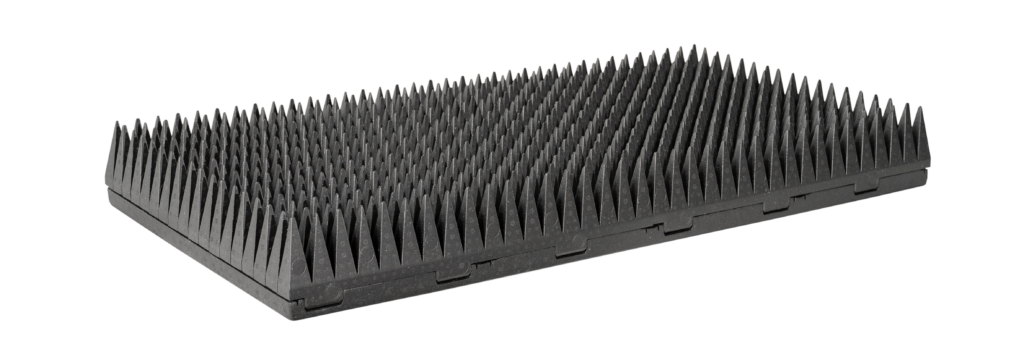

This 5-inch (13cm) absorber is specifically designed for smaller wireless antenna test setups, like OTA boxes or cabinets. The operating frequency is 2GHz up to 110GHz.

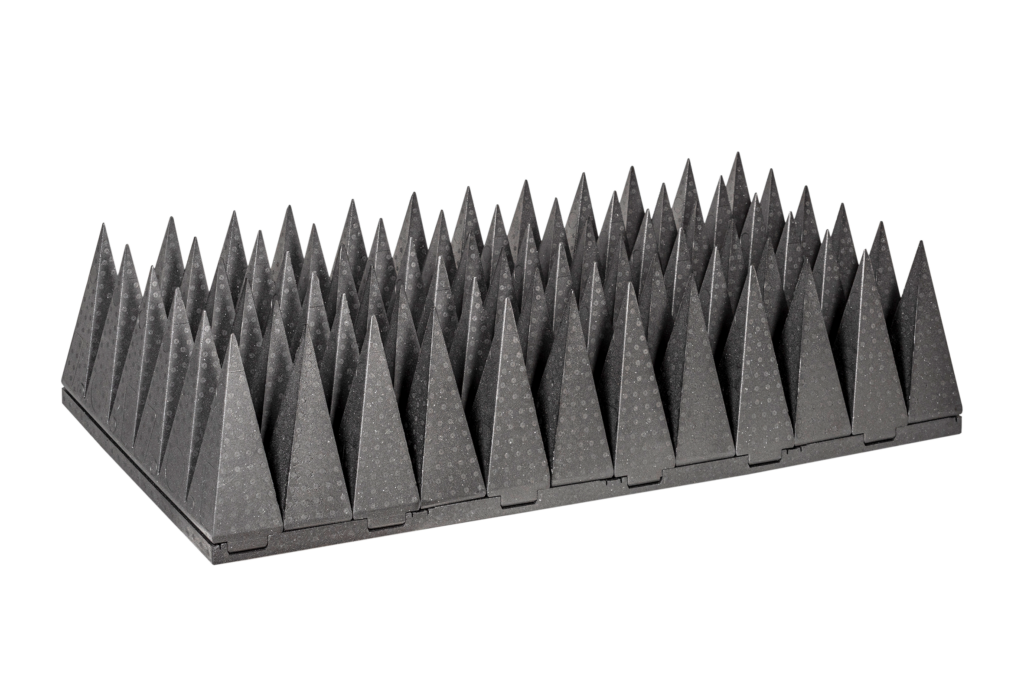

With a total height of 12-inch (30cm) this microwave absorber’ reflectivity performance is outstanding. Among other USP’s, DMAS absorbers are made of expanded polystyrene (EPS) and come with great benefits over traditional foams.

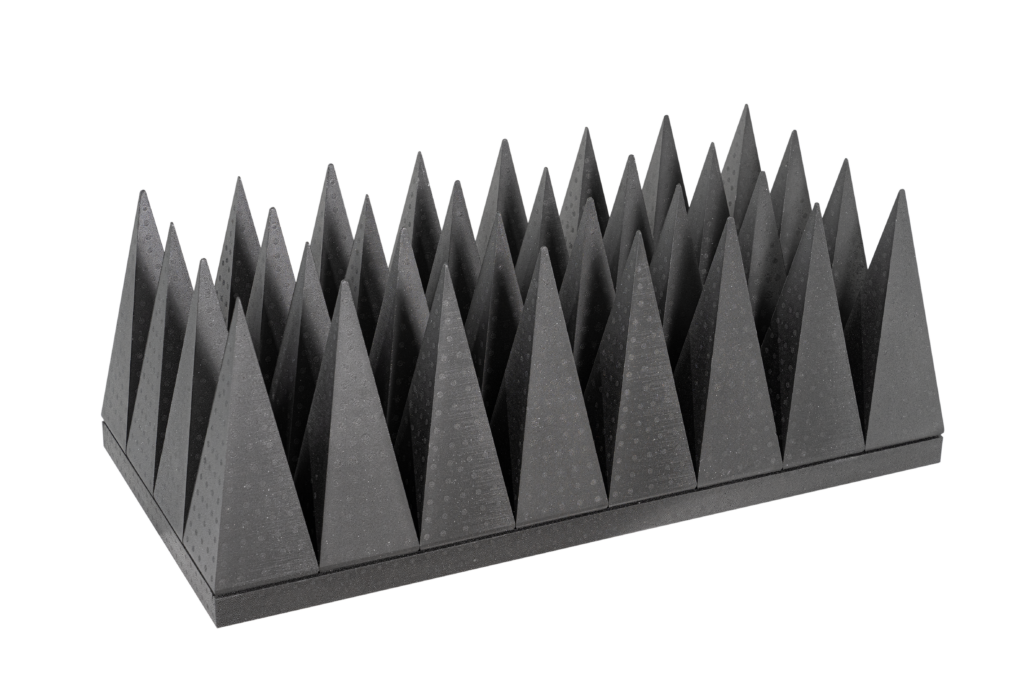

Introducing the MT45-JT (18”) absorber: a long-lasting, javelin-tipped, polystyrene absorber. Among other USP’s, DMAS absorbers are humidity resistant and made of closed-cell material. This provides great benefits over traditional foam materials, such as no leakage of carbon particles.

This polystyrene absorber offers the enormous benefit of meeting reflectivity requirements part of MIL-STD461 guidelines, even when no ferrite tile base is utilized. This means a great cost reduction can be achieved using the MT50 absorber.

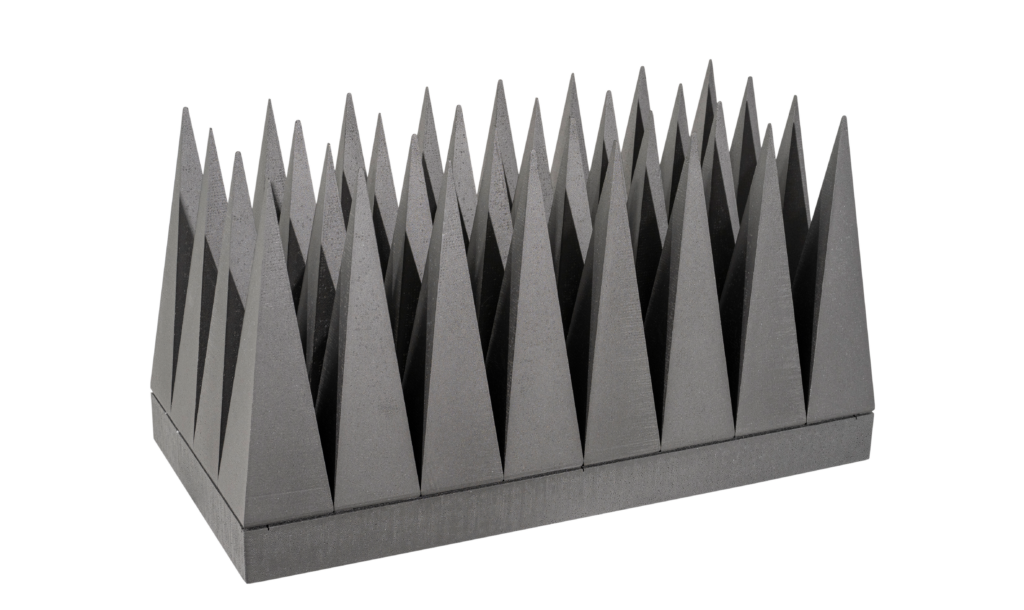

The tallest DMAS absorber is the MT65-JT. This 26-inch absorber is designed for measurements at very low frequencies. Its operating frequency starts at 200MHz. Among other USP’s, DMAS absorbers are lightweight and easy to install. (Adhesive-free installations)

Need quick access to your antenna or Device Under Test (DUT)? Tired of getting first the floor absorbers out of the way before you can make adjustments in your setup? With DMAS walkway absorbers you have an immediate pathway available.

A key advantage of DMAS pyramidal absorbers is that they’re made using polystyrene rather than foam. Now that polystyrene offers incredible performance, there is no reason to equip your testing facilities with inferior alternatives.

Quality testing is done under our own supervision (IEEE std 1128-1998). In addition, ISO 9001 and ISO 14001 standards apply to all production to ensure tight quality control.

Thanks to a clever use of absorbing materials and modern production techniques, pyramidal RF absorbers are fire retardant, durable and able to withstand humidity. This ensures long life and low toxicity.

Quality is our main priority. That’s why DMAS pyramidal absorbers are designed, tested and manufactured in the Netherlands.

A key advantage of DMAS pyramidal absorbers is that they’re made using polystyrene rather than foam. Now that polystyrene offers incredible performance, there is no reason to equip your testing facilities with inferior alternatives.

Thanks to a clever use of materials and modern production techniques, DMAS absorbers are fire retardant, durable and able to withstand humidity. This ensures long life and low toxicity.

Quality testing is done under our own supervision (IEEE std 1128-1998). In addition, ISO 9001 and ISO 14001 standards apply to all production to ensure tight quality control.

Quality is our main priority. That’s why DMAS pyramidal absorbers are designed and made in the Netherlands.

Perhaps it is obvious, but most (if not all) hybrid and microwave absorbers have a pyramid-shaped appearance. This shape is essential in generating the reflectivity that is required to absorb signals and radiation that might otherwise contaminate valuable research. The absorbers are sometimes referred to as ‘pyramidal absorbers’ but DMAS electromagnetic, hybrid and microwave absorbers are essentially the same thing.

Looking for the very best in absorber technology? DMAS absorbers are designed for modern testing facilities and represent the latest in sustainability & performance. Contact us today to get started.

Would you like to discuss a new project or do you want to know more about a specific absorber? Use the form below or call us directly via +31 (0)71 542 1880 for more information.

Hoge Rijndijk 205

2382 AL

Zoeterwoude

The Netherlands

Dutch Microwave Absorber Solutions bv

Hoge Rijndijk 205

2382AL, Zoeterwoude

The Netherlands

+31 (0)71 542 1880

© 2025 | Dutch Microwave Absorber Solutions bv

Hoge Rijndijk 205

2382AL, Zoeterwoude

The Netherlands

+31 (0)71 542 1880

info@dmas.eu

We use cookies to improve your experience on our website, to be able to provide social media services and to analyse our web traffic.