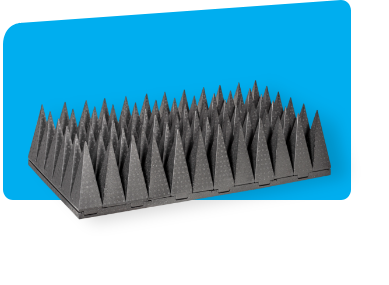

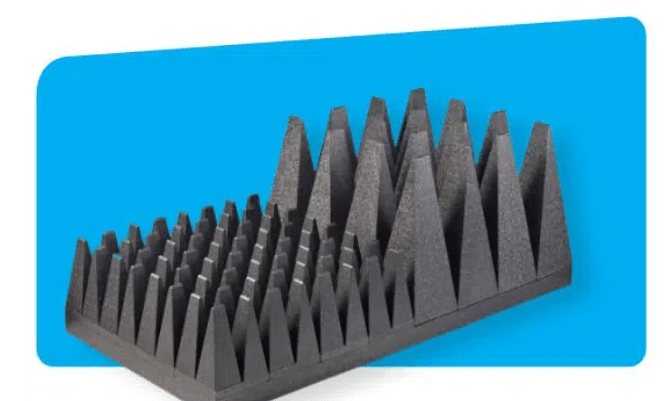

RF absorbers manufactured by DMAS offer outstanding performance as well as exceptional durability due to the use of polystyrene (EPS) material. Our absorbers have a modular design concept consisting of a baseplate and pyramidal shaped cones. The absorber is then installed to chamber walls using mounting profiles and bolts.

In general, our RF absorbers are divided into two product categories, hybrid and microwave absorbers. Tuned for use in semi & full anechoic chamber solutions designed for electromagnetic compatibility testing applications, DMAS hybrid EMC absorbers have pushed the industry forward by using EPS material on top of a ferrite tile base layer.

The second major product category is the DMAS Microwave absorber. Over the last three years, our RF absorbers for use in antenna measurement applications have greatly improved due to changes in raw material an enhanced design that changes its shape from a taper to an almost perfect pyramidal absorber. This leads to significantly increased performance, comparable to traditional foam solutions without compromising eco-friendliness or rigidity. Read more about EPS vs foam in this blog post.

We also offer a high-end walkway absorber with reinforced fiberglass epoxy grid panels for easy access to equipment under test in facilities where the floor is otherwise permanently covered in RF absorbers.

It doesn’t matter whether you’re designing a component for a road vehicle, developing a new wireless router or launching a new type of satellite into orbit, there are strict limits imposed on the amount of electromagnetic interference any new product (or its component parts) can emit. These limits are clearly delineated in various standards that govern different applications. Take for instance the MIL-STD-461 standard which provides the requirements for systems designed for armed forces or the CISPR 25 standard which is an important benchmark for the automotive industry. However, in order to effectively determine whether a new product is compliant, you need to isolate as much interference from outside signals as possible. That is where the RF absorber comes in.

Thanks to a number of smart innovations, DMAS RF absorbers can be made using durable and non-toxic polystyrene material, making it a far better choice than traditional foam absorbers.

DMAS RF absorbers are made right here in the Netherlands. This allows us to guarantee a great product that lasts for a long time.

Unlike competing foam alternatives, DMAS absorbers have all the qualities you need (durability, resistance to humidity, fire retardant) without using hazardous materials during production.

ISO 9001 and ISO 14001 standards apply to production to ensure tight quality control. Testing is done according to IEEE std 1128-1998 standard.

Thanks to a number of smart innovations, DMAS RF absorbers can be made using durable and non-toxic polystyrene, making it a far better choice than traditional foam absorbers.

Unlike competing alternatives, DMAS absorbers have all the qualities you need (durability, resistance to humidity, fire retardant) without using hazardous materials during production.

ISO 9001 and ISO 14001 standards apply to production to ensure tight quality control. Testing is done according to IEEE std 1128-1998 standard.

DMAS RF absorbers are made right here in the Netherlands. This allows us to guarantee a great product that lasts for a long time.

Emissions and immunity testing is most often done in full or semi anechoic chambers. These RF shielded chambers are lined with RF absorbing materials that come in different shapes and sizes. Why do you need an RF absorber? Well, as stated earlier, you can’t test the amount of electromagnetic interference generated by a product until you’ve isolated it from outside interference using an RF shielded enclosure. RF absorbing materials keeps the radiation inside the chamber from bouncing around endlessly, making it much easier to get a clear picture of what is going on with your device/equipment under test.

RF absorbing materials are available in various formats. There are sheets, tiles, wedges, pyramids, convoluted and multilayer broadband absorbers. Still, most facilities opt for the RF absorbers with the classic pyramidal shape since these offer solid performance in commonly tested frequencies. The performance is measured in dB. For instance: if an absorber has a -25 dB level of attenuation, a 10 dB signal will be reduced to -15 dB once it has passed through the absorbing material. There is something else to consider other than the shape of the RF absorber and that is the actual material used.

In addition to a great product, we provide the advice you need to achieve the best results. Feel free to turn to us for expert technical advice. Questions are answered within 24 hours.

DMAS polystyrene absorbers are designed and manufactured in The Netherlands to ensure the highest levels of quality.

DMAS enjoys a close collaboration with Comtest Engineering, one of the foremost suppliers of anechoic chamber solutions. Together, we have over 45 years of experience in the field.

When so much thought is given to an RF absorber’s performance characteristics, it’s easy to forget that the materials used in the production of an absorber are equally important to consider. Foam is the traditional choice. It’s easy to give a foam absorber the desired shape and the performance is generally excellent. There’s a problem though. The carbon which gives a foam absorber its absorbing properties tends to leak and the foam itself deforms over time, this pollutes the research facility and impacts performance over time. For this reason, DMAS has developed a new kind of absorber using expanded polystyrene (EPS). Yes, that’s the stuff used for coffee cups and protecting consumer goods during transit. However, when you treat it just the right way using a special carbon loading technique, polystyrene becomes a very effective RF absorbing material that offers stable performance over decades.

In general, the RF absorbers we produce are divided into two product categories: hybrid and microwave absorbers. Tuned for use in semi & full anechoic chamber solutions designed for electromagnetic compatibility testing applications, DMAS hybrid EMC absorbers have pushed the industry forward by using EPS material on top of a ferrite tile base layer.

The second major product category is the Microwave absorber. Over the few years, our RF absorbers for use in (among others) near-field, far-field measurement applications, among others, have greatly improved due to changes in raw material and enhanced design that changes its shape from a taper to an almost perfect pyramidal absorber. This leads to significantly increased performance comparable to traditional foam solutions without compromising eco-friendliness or rigidity.

Of course, sometimes you’re willing to sacrifice an acceptable amount of performance for a significant increase in the level of access for your engineers. For full anechoic chambers that require easy access to equipment under test, consider using a DMAS walkway absorber. The reinforced fiberglass epoxy grid panels are strong enough to walk on without compromising the integrity of your research.

If you are an honest-to-goodness, ‘gen-you-whine’ science man or woman and you’re thinking to yourself ‘this is all well and good, but this information is rather basic and I have this flux capacitor here and I need to know exactly what kind of absorber configuration I would need to achieve optimal reflectivity when I launch this across the facility at 88 miles an hour,’ don’t you worry, we have qualified engineers at DMAS for you to talk to and discuss the minutest of details with.

DMAS RF absorbers are manufactured using EPS to achieve excellent performance and stability. Do you want to learn more about RF absorbing materials? Contact our experts today and let’s talk. We can help you decide what is likely to work best for your facility and research.

Dutch Microwave Absorber Solutions bv

Hoge Rijndijk 205

2382AL, Zoeterwoude

The Netherlands

+31 (0)71 542 1880

© 2024 | Dutch Microwave Absorber Solutions bv

Hoge Rijndijk 205

2382AL, Zoeterwoude

The Netherlands

+31 (0)71 542 1880

info@dmas.eu

We use cookies to improve your experience on our website, to be able to provide social media services and to analyse our web traffic.